| Steptronic, Tiptronic, Geartronic – Ah, What's the Difference? | 您所在的位置:网站首页 › steptronic › Steptronic, Tiptronic, Geartronic – Ah, What's the Difference? |

Steptronic, Tiptronic, Geartronic – Ah, What's the Difference?

Technically Speaking

Author: By Wayne Colonna, Technical Editor

Technically Speaking

Author: By Wayne Colonna, Technical Editor

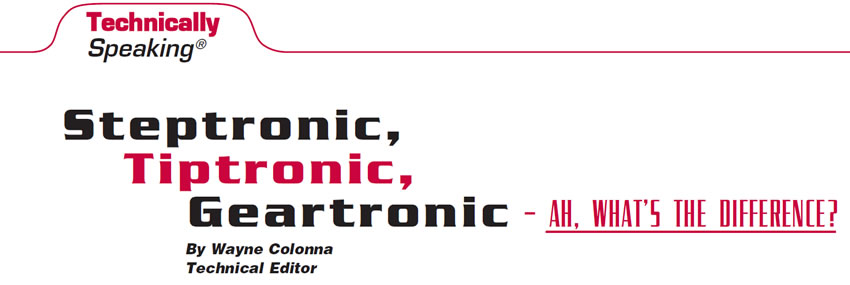

I am always amused by the many different names we see that are used to describe basically the same device. For example, we have a pressure-control solenoid, or we could call it an EPC (electronic pressure-control) solenoid, a force motor or a linear solenoid. We have the same thing with what Chrysler has called an Autostick, which now is being referred to as a J Gate, Steptronic, Tiptronic or Geartronic – how Ironic (see Figure 1). Related Articles - Transmission fluid hydraulics - The ins and outs of transmission diagnostics - Mazda FW6A-EL stored pressure switch codes

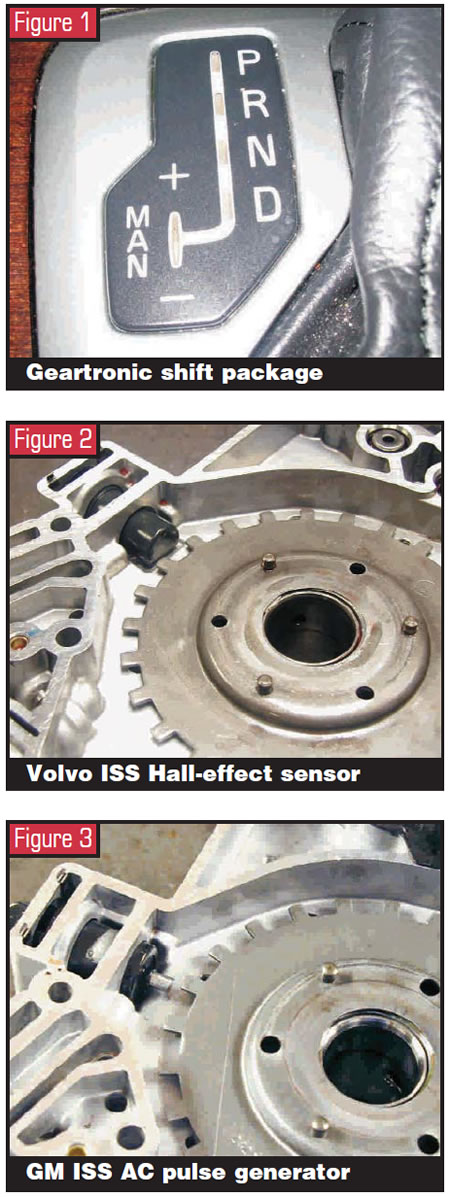

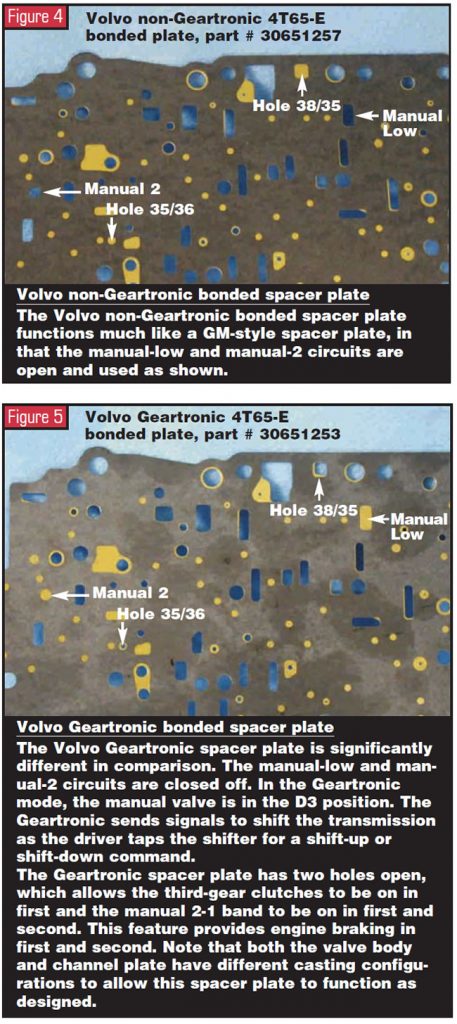

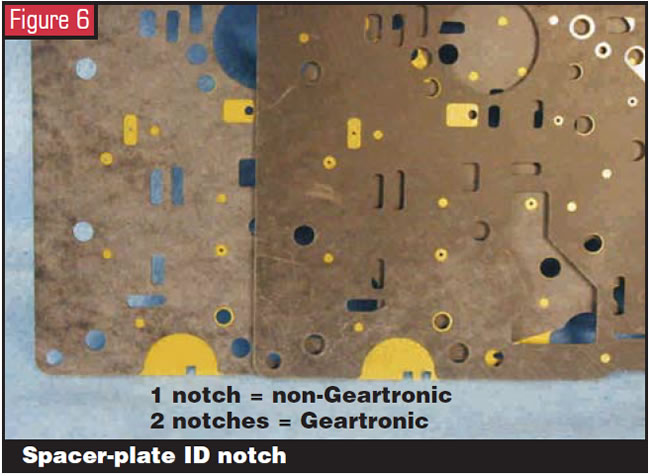

The Geartronic shifter is the term used in Volvo applications in the United States. This article makes reference to Volvo applications fitted with a GM 4T65-E transaxle. This transmission has many significant differences between GM and Volvo applications. We covered one such difference in the June 2005 issue of Transmission Digest. Volvo uses a Hall-effect sensor for the input-speed sensor (ISS); GM uses an AC pulse generator (see figures 2 and 3). These will not interchange, as the June article explains. But some of the other significant differences include the channel plate, spacer plate and valve body. That is between GM and Volvo. But the 4T65-E in Volvo applications can differ depending on whether it is equipped with a Geartronic package. A non-Geartronic package has the typical manual valve with seven detent positions: P, R, N, OD, 3, 2, 1. Figure 4 shows the spacer plate for this arrangement.

As shown in Figure 1, the Geartronic package has the positions P, R, N, D and plus/minus manual-shift detent positions. Figure 5 shows the spacer plate for this configuration. With this style of shifter, the lowest position into which the manual valve could be placed by the shift lever is D3. This is the position in which the driver can manually tip up or tip down to change gears. As you compare the non-Geartronic plate with a Geartronic plate, you can see in the Geartronic plate that the manual-low and manual-2 oil circuits have been closed and two other holes have been opened: 38/35 and 35/36. This configuration allows for engine braking in first and second gears while the manual valve is in the D3 position. You can quickly imagine some of the effects that would occur with the use of incorrect spacer plate. One of the more-common mismatches we have experienced through ATSG’s tech line is when a technician installs a Geartronic spacer plate in a GM 4T65-E. There will be no movement in D3 or lower. If a Volvo non-Geartronic plate is used in a Geartronic application, there will be no engine braking in tip-up or tip-down first or second gear. If a Geartronic plate is used in a Volvo non-Geartronic application, there will be no engine braking in the manual-low or manual-2 position. Figure 6 shows how to tell the difference between non-Geartronic and Geartronic plates to help prevent incorrect usage of the plates.

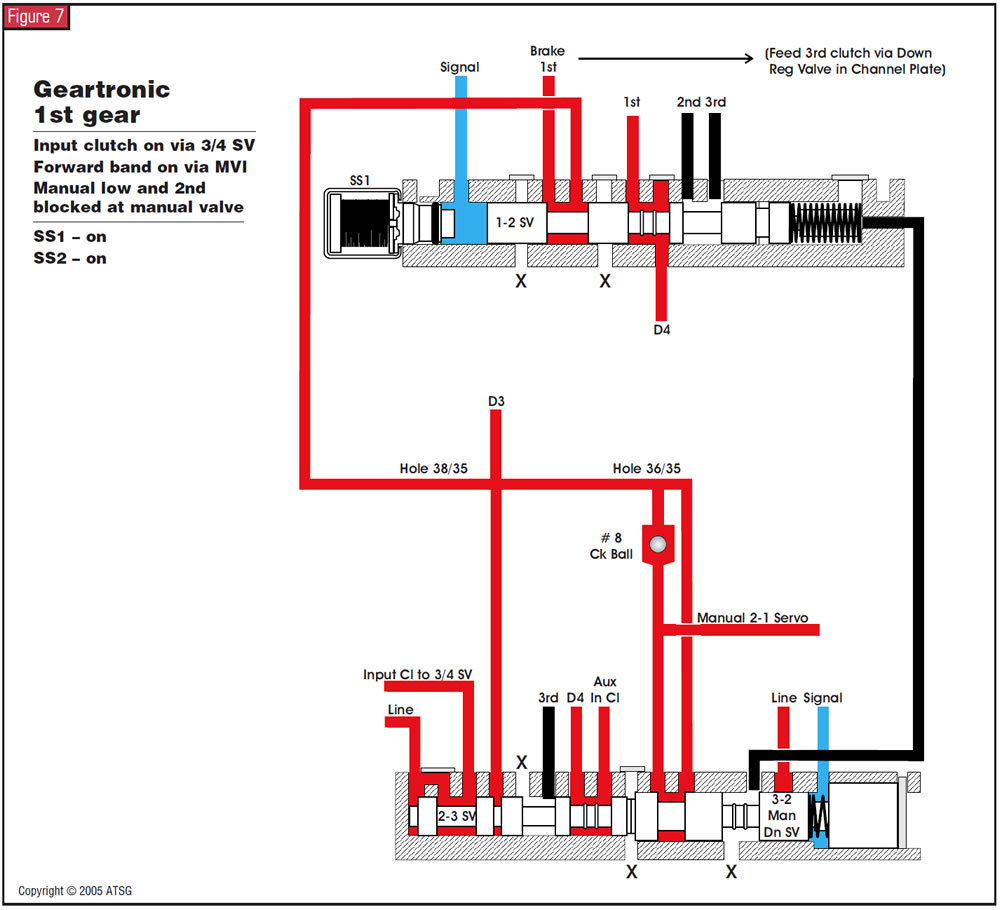

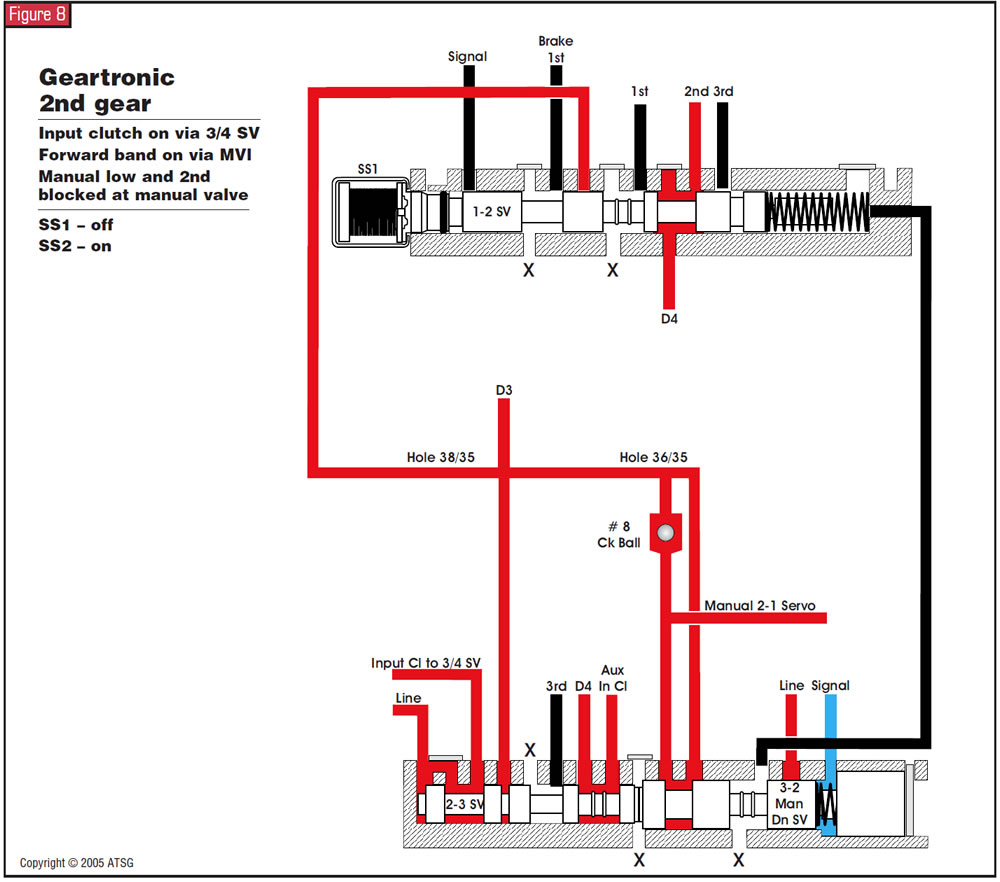

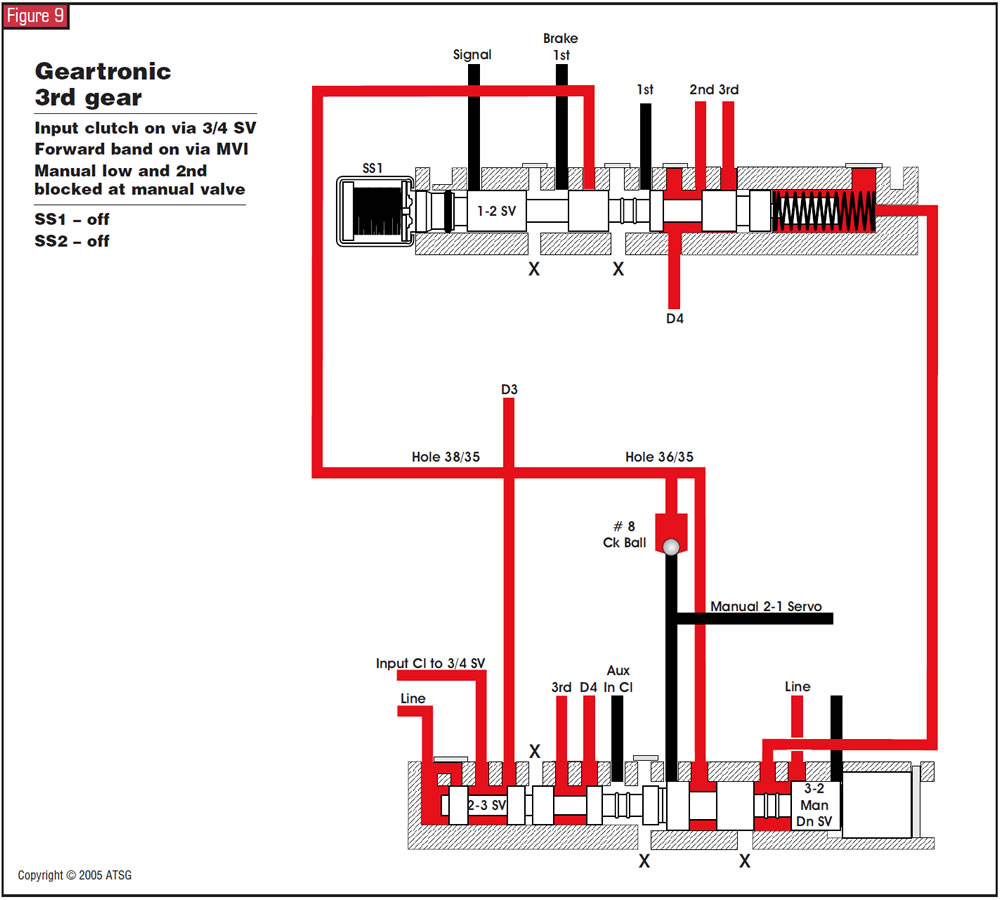

Figures 7, 8 and 9 are partial hydraulic schematics showing how the manual-low and manual-2 circuits being blocked and holes 38/35 and 35/36 being open will allow for engine braking in a tip-up or tip-down into first or second while the manual valve remains in the D3 position.

|

【本文地址】