| 最常用的酸催化酯化反应 | 您所在的位置:网站首页 › 对甲苯磺酸的用途 › 最常用的酸催化酯化反应 |

最常用的酸催化酯化反应

|

【 Chem. Commun. , 1997, 351-352】 【 Tetrahedron , 2002, 58, 8179-8188】 【 Tetrahedron , 2003, 59, 3627-3633】 【 J. Am. Chem. Soc. , 2005, 127, 4168-4169】 【 Synthesis , 2008, 3407-3410】 【 J. Org. Chem. , 2005, 70, 8625-8627】

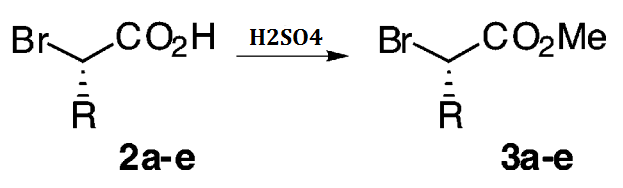

The α-bromoacid was treated with a solution of concentrated sulphuric acid (30 µL/mmol) in methanol (2 mL/mmol) and refluxed for one hour. The solution was cooled to room temperature and concentrated in vacuo. Et2O was added and the organic layer was washed with 5% aqueous solution of NaHCO3 followed by brine, dried over MgSO4 and concentrated in vacuo. 【 J. Org. Chem. , 2006, 71, 3332-3334】 【 J. Org. Chem. , 2009, 74, 5967-5974】 【 Synlett , 2017, 28, 981-985】 二、实例操作 1、 硫酸作催化剂的酯化反应示例: 4-Amino-3-nitrobenzoic acid (200.0 g) was suspended in ethanol (1030 g).Conc. sulfuric acid (120.0 g) was added dropwise to the mixture over 0.5 h.After the dropwise addition, the mixture was refluxed under heating for 15 h. Apart (422 mL) of ethanol was distilled away at atmospheric pressure, and water(660 mL) was added dropwise to allow precipitation of crystals. To this suspension were added 25% aqueoussodium hydroxide solution (50 mL) and then 2.5% aqueous sodium hydroxidesolution (262 mL), and pH was adjusted to 6.5. The precipitated crystals werecollected by filtration, washed successively with ethanol (531 mL) and water(1069 mL), and dried under reduced pressure to give ethyl4-amino-3-nitrobenzoate (200.6 g)。 2 、盐酸(氯化氢)作催化剂的酯化反应示例: 3,4-Diaminobenzoic acid (152 g, 1.0 mol) was stirred with ethanol (2000mL) in a Morton flask. Hydrogen chloride gas was passed through the stirredsuspension for about 2 h. As the gas was absorbed, the slurry became gel-likein character. Ethanol (500 ml.) was added to the reaction mixture to dispersethe gel. The reaction mixture was refluxed 24 h. The mixture was filtered andthe filtrate was evaporated to dryness in vacuo. The filter cake and thefiltrate residue were dissolved in water (9 L). Theaqueous solution was made basic by the addition of solid sodium carbonate. Theproduct precipitated from the basic solution. The material was filtered anddried to yield ethyl 3,4-diaminobenzoate (130 g, 72.14%)。 3 、氯化亚砜作催化剂的酯化反应示例: To a suspension of 6-chloropyridine-2-carboxylic acid (8.3 g, 0.0525mol) in dioxane (25 mL), thionyl chloride (9.4 mL, 0.13 mol) was added and theresulting mixture was stirred at 70℃for 4 h. The reaction mixture was concentrated invacuo and a mixture of dioxane (8.3 mL) and ethanol (16.6 mL) was added. Thereaction mixture was heated to 70℃for 2 h, triethylamine (8.3 mL), ethanol (4.1 mL) andwater (8.3 mL) were added and the reaction mixture was again concentrated. Theresidue was distributed between diethyl ether (28 mL) and water (18 mL) and thephases were separated. The aqueous layer was extracted with diethyl ether (30mL) and the combined organic layers were dried over MgSO 4 , filteredand evaporated in vacuo to afford 6-chloropyridine-2-carboxylic acid ethylester (8.82 g, 91%) as oil。 4 、乙酰氯作催化剂的酯化反应示例: Acetyl chloride (15.3 mmol) was added dropwise to ethanol (50 mL) at 0℃. After 30 min, the acid (7.69 mmol) was added and thereaction mixture was heated at reflux for 15 h. The reaction mixture wasconcentrated and the residue was partitioned between dichloromethane (20 mL)and saturated sodium bicarbonate (10 mL). The aqueous layer was furtherextracted with dichloromethane (20 mL ×2) and the combined organic layers were dried(magnesium sulfate) and concentrated to provide the ester in 94% yield as brown oil。 主要起作用的应该是乙酰氯和乙醇反应生成的HCl。 5、 对甲苯磺酸作催化剂的酯化反应示例: 对甲苯磺酸作酯化催化剂只比硫酸稍弱,仍是一个强酸,其用量与使用硫酸相等,其作用相近,使用对甲苯磺酸作为酯化催化剂主要是为了避免硫酸带来的焦化和其他副反应。 A 300-mL, one-necked,round-bottomed flask was equipped with a magnetic stirrer, Dean-Stark trap, and a reflux condenser. The flask was charged with 3.0 g (20 mmol) of L-(+)-tartaric acid, 6.5 g (60 mmol) of benzyl alcohol, 47.5 mg (0.25 mmol) of p-toluenesulfonic acid monohydrateand 40 mL of toluene. The mixture washeated under reflux in an oilbath (about 130℃) for 13 h r.During this period the theoretical amount of water (0.62 mL) was collected. Themixture was allowed to cool to ambient temperature, diluted with ether, and poured into 50 mL of aqueous, saturated sodium bicarbonate. Theorganic phase was separated and the aqueous phase was extracted twice with 20 mL of ether. The combinedorganic phases were dried over sodiumsulfate. The solvent was removed with a rotary evaporator, and the resulting crudeproduct was triturated with hexane-ether (20:1, 210 mL) to give white crystals of (−)-dibenzyl tartrate.The precipitate was collected by filtration and washed with hexane-ether (20:1). Thefiltrate was further concentrated to give a second crop. The total yield was 6.2 g (94%), mp 49–50 ℃ 三、酯交换

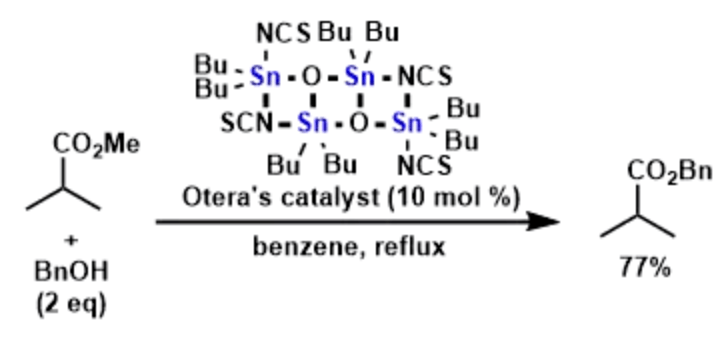

【 J. Org. Chem. , 1991, 56, 5307-5311】

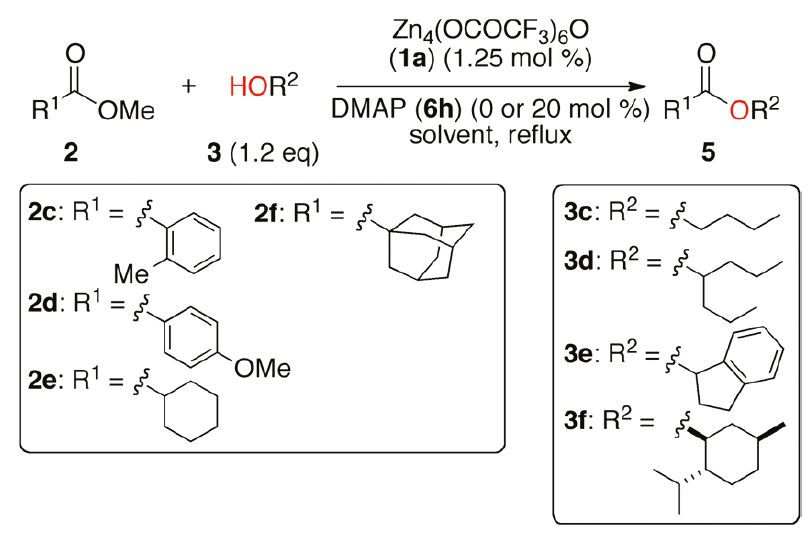

【 ACS Catal. , 2011, 1, 1178–1182】 相关文献 1. Fischer, E.; Speier, A. Ber. Dtsch. Chem. Ges. 1895, 28, 3252-3258. 2. Hardy, J. P.; Kerrin, S. L.; Manatt, S. L. J. Org. Chem. 1973, 38, 4196-4200. 3. Fujii, T.; Yoshifuji, S. Chem. Pharm. Bull. 1978, 26, 2253-2257. 4. Pcolinski, M. J.; O’Mathuna, D. P.; Doskotch, R. W. J. Nat. Prod. 1995, 58, 209-216. 5. Kai, T.; Sun, X.-L.; Tanaka, M.; Takayanagi, H.; Furuhata, K. Chem. Pharm. Bull. 1996, 44, 208-211. 6. Birney, D. M.; Starnes, S. J. Chem. Educ. 1996, 76, 1560-1561. 7. Cole, A. C.; Jensen, J. L.; Ntai, I.; Tran, K. L. T.; Weaver, K. J.; Forbes, D. C.; Davis, J. H., Jr. J. Am. Chem. Soc. 2002, 124, 5962-5963. 8. Li, J. in Name Reactions for Functional Group Transformations, Li, J. J., Ed., Wiley: Hoboken, NJ, 2007. pp 458-461. 9. Saavedra, H. M.; Thompson, C. M.; Hohman, J. N.; Crespi, V. H.; Weiss, P. S. J. Am. Chem. Soc. 2009, 131, 2252-2259. 参考资料 一、 Name Reactions (A Collection of Detailed Reaction Mechanisms), Jie Jack Li, Fischer-Speier esterification,page 252. 二、Organic Chemistry Portal:https://www.organic-chemistry.org/namedreactions/fischer-esterification.shtm 三、化学空间:https://cn.chem-station.com/reactions/2016/01/post-8092.html返回搜狐,查看更多 |

【本文地址】