| 反射镜(mirrors) | 您所在的位置:网站首页 › 光线反射镜2 › 反射镜(mirrors) |

反射镜(mirrors)

|

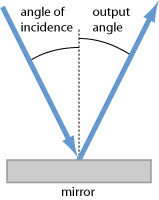

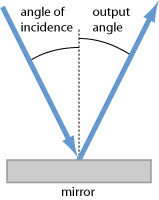

反射镜(mirrors) 定义:可以反射光的器件。 反射镜是能够反射光的光学器件。但是,只有当入射角等于反射角的光学装置才称为反射镜(如图1)。这表示衍射光栅等,并不能称作反射镜,尽管它们可以反射光。 反射镜表面不一定是平的,存在曲面反射的反射镜。 反射镜的性质  图1:反射镜反射光。反射镜具有一些基本的性质: 反射率是反射光功率所占的百分比。通常它与波长和入射角有关,还与偏振方向有关。 反射相位是反射光的相移,即光反射前后光产生的相位变化。相移与波长和偏振方向有关。如果s偏振和p偏振的相位变化不同(非垂直入射),那么即使入射光是纯s或p偏振,入射光偏振态反射后都会发生改变。 反射镜只工作于有限波长范围,只有在该区域才能得到需要的反射率。该区域宽度称为反射带宽。带宽值与入射角度、偏振态还有反射率允差有关。 入射角范围也是有限的,尤其是对于介质反射镜。在许多应用中还需要考虑其他的一些性质: 在激光器技术中需要很高的表面质量。表面平滑度通常用波长表征,例如λ / 10。由于表面缺陷很大程度上是一个随机现象,只能给出其统计学表征。对于小的局部缺陷,常用“划痕和坑”来表征。其中包含划痕的最大长度(十分之一微米)和坑的最大半径(百分之一微米)。例如,划痕-坑的值为20-10表明划痕的最大长度为2微米,坑的最大直径为0.1微米。 当采用高功率激光器时,需要考虑光学损伤阈值,尤其是脉冲激光器,因为其峰值功率很高。反射镜类型 金属反射镜通常的家用反射镜为银反射镜。是由金属盘并且其一侧涂覆银涂层得到的。涂层足够厚可以抑制两边光的透射。然而,反射率比100%小,因为银涂层会吸收一部分的光。家用反射镜的涂层通常是位于内侧,外面是玻璃表面,很容易清洗。其它应用中,光通常直接入射到涂层上,而不需要射到衬底上。 激光器技术和基础光学中,存在更先进的金属反射镜。这些反射镜的表面通常还有附加的涂层是为了提高反射率同时保护金属涂层避免被氧化。可以采用多种金属做反射镜涂层,例如,金,银,铜和镍铬合金。 词条金属反射镜中有更多的细节。 介质反射镜激光器技术和基础光学中最重要的反射镜为介质反射镜。这种反射镜包含多层薄介质涂层。它是利用不同涂层截面的反射效应结合在一起。常用的一种类型为布拉格反射镜(四分之一波长反射镜),这是最简单的在某一波长(布拉格波长)处能得到最高反射率的一种反射镜。 参阅词条介质反射镜得到更多细节。 常采用激光反射镜形成激光器谐振腔,通常为介质反射镜,具有很高的光学质量和高的光学损伤阈值。还存在超级反射镜,其反射率非常接近100%,而啁啾反射镜则具有系统厚度变化的薄膜。 曲面反射镜大多数曲面反射镜的表面的球形的,由曲率半径R表征。凹面反射镜表面是作为聚焦反射镜,而凸面则具有散焦的行为。除了光束方向发生变化,这一反射镜更像是一个透镜。正入射的情况下,焦距为R / 2,即曲率半径的一半。而非垂直入射入射角为θ 时,焦距在切平面上为(R / 2) • cos θ,矢状面上为(R / 2) / cos θ。 还有抛物线反射镜,其表面为抛物线型。紧聚焦的情况下,通常采用轴外抛物线反射镜,这样得到的焦点在入射光束外面。 二向色镜二向色镜是对于两个不同波长的光的反射特性完全不同。它通常是合适设计的薄层介质反射镜。 Definition: devices which reflect light More general term: reflectors More specific terms: metal-coated mirrors, dielectric mirrors, Bragg mirrors, crystalline mirrors, first surface mirrors, parabolic mirrors, variable reflectivity mirrors, deformable mirrors, laser mirrors, laser line mirrors, fiber loop mirrors, semiconductor saturable absorber mirrors, supermirrors A mirror is an optical device which can reflect light. Usually, only those devices are meant where the reflection is of specular type and the angle of reflection equals the angle of incidence (see Figure 1). This means that reflective diffusers and diffraction gratings, for example, are not considered as mirrors, although they can also reflect light. A somewhat more general term is reflector. While all mirrors are reflectors, there are reflectors which are somewhat more complex than a simple mirror, e.g. prisms used as retroreflectors, using more than one total internal reflection at a prism surface. Mirror surfaces are not necessarily flat; there are mirrors with a curved (convex or concave) reflecting surface (see below). This article deals mostly with optical mirrors as used in optics and laser technology, for example, and in other areas of photonics. Properties of a MirrorVarious basic properties characterize a mirror:  Figure 1: Reflection of light on a mirror. The reflectivity (or reflectance) is the percentage of the optical power which is reflected. Generally, it depends on the wavelength and the angle of incidence, for non-normal incidence often also on the polarization direction.The reflection phase is the phase shift of reflected light, i.e., the optical phase change obtained when comparing light directly before and directly after the reflection. The phase shift can depend on the wavelength and the polarization direction. If the phase change is different between s and p polarization (for non-normal incidence), the polarization state of incident light will in general be modified, except if it is purely s or p polarization. That is exploited in phase-retarding mirrors, e.g. for converting linearly polarized light into circularly polarized light.Mirrors work only in a limited wavelength range, i.e., they exhibit the wanted reflectivity only within that range. The width of that range is called the reflection bandwidth. Of course, its exact value generally depends on the angle of incidence, the polarization and on the tolerance for the reflectivity.Similarly, there can be a limited range of angles of incidence, particularly for dielectric mirrors.The surface shape (e.g. spherically convex curved) is also relevant, see below.Additional properties can be relevant in various applications: A high surface quality is often important in laser technology. The surface flatness of laser mirrors and others is often specified in wavelengths, e.g. λ / 10. As surface defects are largely a random phenomenon, only worst-case or statistical specifications can be given. For small localized defects, it is common to give “scratch & dig” specifications according to the US standard MIL-REF-13830B: there are two numbers, quantifying the severity of scratches (shallow markings or tearings) and digs (pit-like holes) basically by a comparison of their visual appearance with those of defects in certain standard parts. A quality figure of simple parts could be 80-50, a commercial quality is 60-40, laser mirrors should normally have 20-10 or better, and high precision parts can have 10-5. There is also the standard ISO 10110-7, which also contains a more rigorous definition based on the size of defects rather than only their visual appearance.For use with high-power lasers, the optical damage threshold may be of interest – particularly in conjunction with pulsed lasers, as these tend to have high peak powers. It is often specified for nanosecond pulses.Types of MirrorsMetal-coated Mirrors – Back Side and First Surface MirrorsOrdinary mirrors as used in households are often silver mirrors on glass. These basically consist of a glass plate with a silver coating on the back side. The coating is thick enough to suppress any significant transmission from any side. Nevertheless, the reflectivity is substantially below 100%, since there are absorption losses of a few percent (for visible light) in the silver layer. Household mirrors typically have the coating on the back side, so that one has a robust glass surface outside, which can be cleaned easily, and the coating on the back side (with an additional layer) is well protected. For other applications, one uses first surface mirrors, where the light is incident directly on the coating and does not reach the mirror substrate. For use in laser technology and general optics, more advanced types of metal-coated mirrors have been developed. These often have additional dielectric layers on top of the metallic coating in order to improve the reflectivity and/or to protect the metallic coating against oxidation (enhanced and protected mirrors). Different metals can be used, e.g. gold, silver, aluminum, copper, beryllium and nickel/chrome alloys. Silver and aluminum mirrors are particularly popular. Others are mostly used as infrared mirrors. The article on metal-coated mirrors gives more details. Dielectric MirrorsThe most important type of mirror in laser technology and general optics is the dielectric mirror. This kind of mirror contains multiple thin dielectric layers. One exploits the combined effect of reflections at the interfaces between the different layers. A frequently used design is that of a Bragg mirror (quarter-wave mirror), which is the simplest design and leads to the highest reflectivity at a particular wavelength (the Bragg wavelength). In contrast to some metal-coated mirrors, dielectric mirrors are usually made as first surface mirrors, which means that the reflecting surface is at the front surface, so that the light does not propagate through some transparent substrate before being reflected. That way, not only possible propagation losses in the transparent medium are avoided, but most importantly additional reflections at the front surface, which could be particularly relevant for non-normal incidence. Generally, dielectric mirrors have a limited reflection bandwidth. However, there are specially optimized broadband dielectric mirrors, where the reflection bandwidth can be hundreds of nanometers. Some of those are used in ultrafast laser and amplifier systems; they are sometimes called ultrafast mirrors, and they also need to be optimized in terms of chromatic dispersion. Laser mirrors as used to form laser resonators, for example, are also usually dielectric mirrors, having a particularly high optical quality and often a high optical damage threshold. Some of them are used as laser line optics, i.e., only with certain laser lines. Also, there are supermirrors with a reflectivity extremely close to 100%, and dispersive mirrors with a systematically varied thin-film thickness. They can be used for high-Q optical resonators, for example. In some cases, dielectric mirrors should also be polished on the back side – in particular, when some amount of light transmission is required, e.g. for output couplers of lasers. Dielectric mirrors can be designed as cold mirrors or hot mirrors, which both can be used for removing unwanted infrared radiation – usually for reducing the thermal load on an optical system. See the article on dielectric mirrors for more details. Dichroic MirrorsDichroic mirrors are mirrors which have substantially different reflection properties for two different wavelengths. They are usually dielectric mirrors with a suitable thin-film design. For example, they can be used as harmonic separators in setups for nonlinear frequency conversion. Curved MirrorsWhile many mirrors have a plain reflecting surface, many others are available with a curved (convex or concave) surface, for example for focusing laser beams or for imaging applications. Most curved mirrors have a spherical surface, characterized by some radius of curvature R. A mirror with a concave (inwards-curved) surface acts a focusing mirror, while a convex surface leads to defocusing behavior. Apart from the change of beam direction, such a mirror acts like a lens. For normal incidence, the focal length (disregarding its sign) is simply R / 2, i.e., half the curvature radius. For non-normal incidence with an angle θ against the normal direction, the focal length is (R / 2) · cos θ in the tangential plane and (R / 2) / cos θ in the sagittal plane. There are also parabolic mirrors, having a surface with a parabolic shape. For tight focusing, one often uses off-axis parabolic mirrors, which allow one to have the focus well outside the incoming beam. Deformable MirrorsThere are deformable mirrors, where the surface shape can be controlled, often with many degrees of freedom (possibly several thousands). Such mirrors are mostly used in adaptive optics for correcting wavefront distortions. Variable Reflectivity MirrorsWhile most mirrors have a uniform reflectance across their reflecting area, there are also variable reflectivity mirrors, where the reflectance depends on the position. These are also called graded reflectivity mirrors. They are used in lasers with unstable resonators, also as variable optical attenuators. Mirrors for Special FunctionsSome types of mirrors are used for special functions: Phase-retarding MirrorsPhase-retarding mirrors are made such that they introduce a well defined phase difference for s- and p-polarized components of a beam. For example, they can be used for converting linearly polarized light into circularly polarized light if that phase difference is π/2. Absorbing Thin-film ReflectorsAbsorbing thin-film reflectors are metal-coated mirrors which are designed to reflect e.g. s-polarized light at 45° angle of incidence while absorbing p-polarized light with the same direction of incidence. They work e.g. at the common CO2 laser wavelength of 10.6 μm and can be used in conjunction with a phase-retarding mirror to build a kind of polarization-based optical isolator. Such a device can e.g. be used for preventing light reflected on a workpiece from getting back to the laser. However, it can be used only for moderate power levels, because otherwise the absorbed power would destroy the mirror or at least degrade its performance. Substrate ShapesMirror substrates in optics and laser technology often have a cylindrical form, for example with a diameter of 1 inch and a thickness of a couple of millimeters. However, there are also substrates with a rectangular, elliptical or D-shaped front surface, for example. Besides, there are prism mirrors, where a reflecting coating is placed on a prism, and retroreflectors. For special applications, a mirror substrate with a tiny hole is used. This can be useful, for example, for combining two laser beams, one of which is sent in a focused fashion through the hole while the other beam, having a substantially larger diameter, is reflected on the mirror surface. Mirrors in Fiber OpticsIn fiber optics, it is also often required to reflect light – in most cases back into the fiber where the light came from. That can be achieved simply by butting a normal kind of mirror (e.g. a dielectric mirror] to a normally cleaved fiber end. Alternatively, one may apply a dielectric coating directly on a fiber end. There are also completely different types of fiber reflectors, e.g. fiber loop mirrors which are strictly speaking no mirrors but another type of reflectors. |

【本文地址】